Huirui independently designed and developed a variety of coaxial cladding nozzles to meet the quality and accuracy requirements of laser cladding for different industrial applications, to achieve the best cladding efficiency.

1. It is more stable and more resistant to defects such as pores, bumps and directional difference;

2. Good focusing performance, easy to adjust the focal plane to match the laser spot ;

3. High powder usage rate;

4. Self-adaptive deposition thickness, to avoid uneven cladding surface and ensure a stable cladding process.

Product advantages:

1. The coaxial annular nozzle has excellent focusing performance The minimum powder spot diameter can reach 0.6mm, and the powder usage rate can reach above 90%.

2. 2. Three-point and four-point coaxial nozzles are have 3 and 4 powder outlets arranged in a circular way. The powder focus is formed by 3 and 4 individual powder beams. inlet and outlet powders, which They are suitable for larger powder feeding, which can meet more higher efficiency t cladding requirements.

3. 3. Linear nozzle is specially designed for use with rectangular or scanned line laser spots. It can meet the need for efficient and stable cladding at higher laser power (≥4kw).

4. Standard connector to Huirui laser head. All the nozzles can used and replaced according to process requirements.

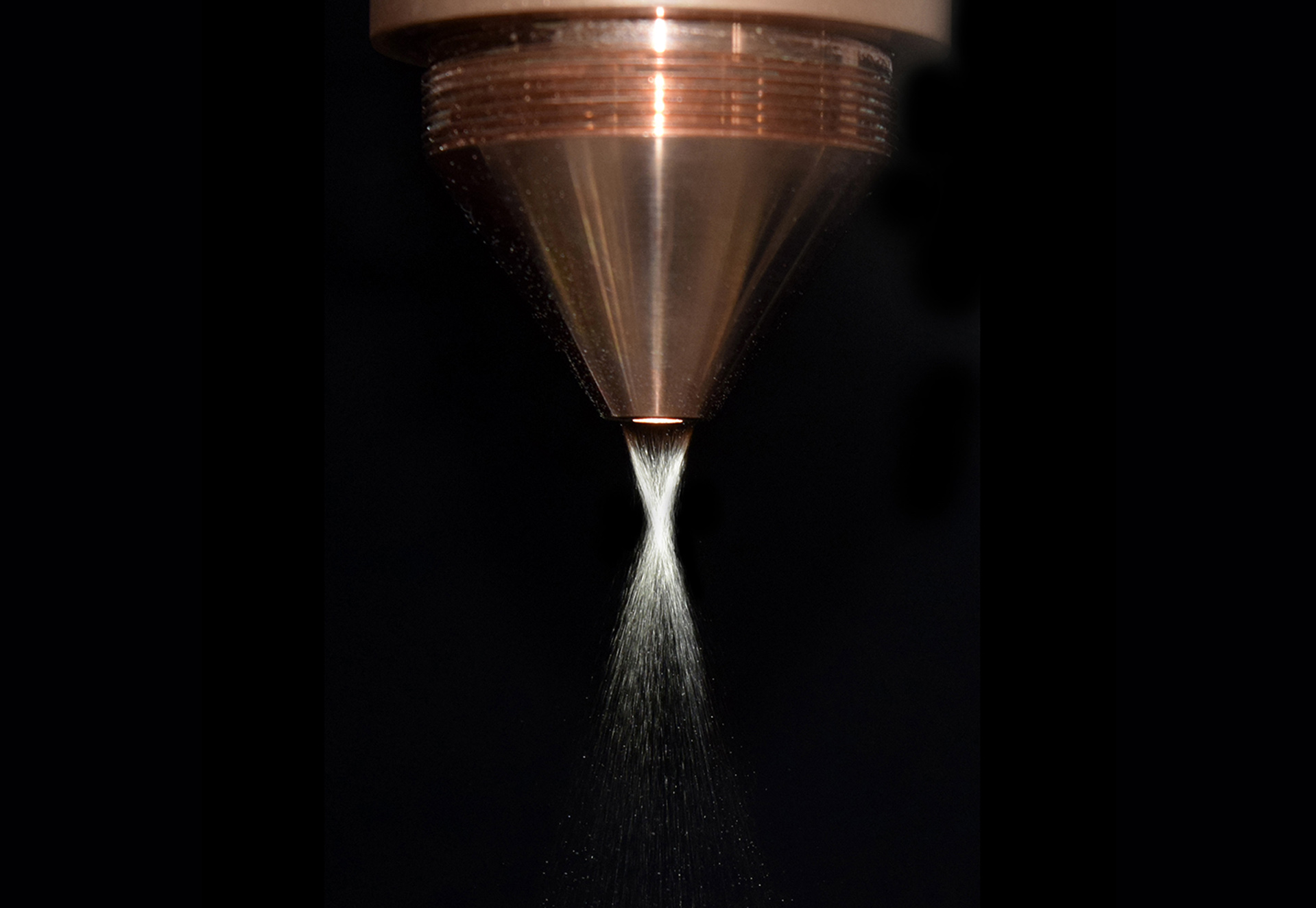

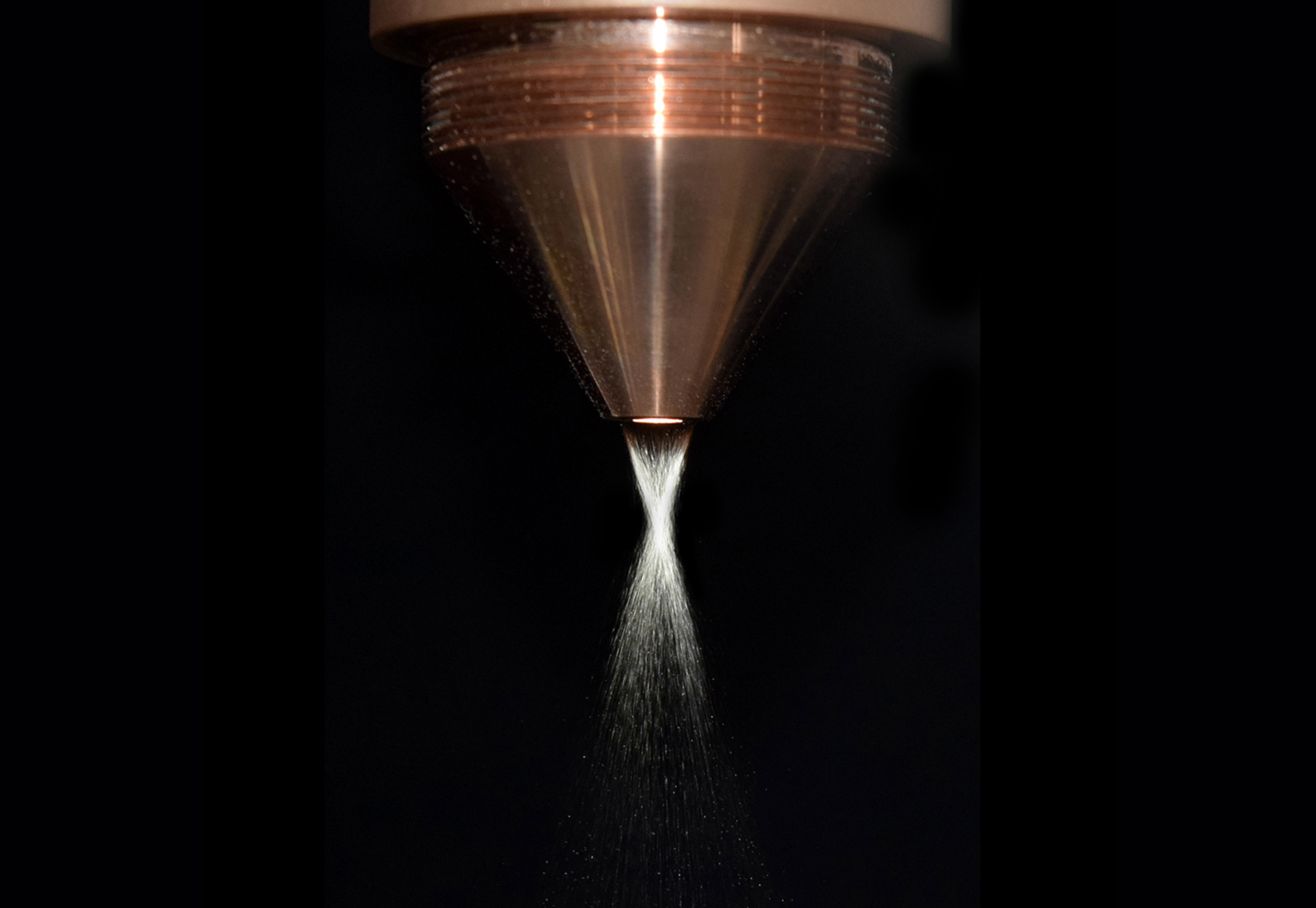

Coaxial annular nozzle (CN-C)

Huirui's coaxial annular nozzle is specially designed for high accuracy parts. . It uses is made of red copper which has high thermal conductivity. The nozzle delivers fine powder beam and can form fine and dense coatings. It is suitable for high accuracy cladding.

Technical Data

|

Model |

LAMCN-C |

|

Type |

coaxial |

|

Powder spot shape |

round |

|

Cooling method |

Water cooling |

|

Minimum powder spot diameter |

0.6mm |

|

Powder feeding rate |

1-15 g/min |

|

Powder particle size |

53-150μm |

|

Size |

100×114.5×49 |

|

Weight |

0.62kg |

|

Gas curtain protection module |

Optional |

|

Recommended laser power |

<1KW |

|

Working distance |

8.1mm |