Remanufacturing and repairing damaged parts is an important way to restore huge economic and time losses, improve resource utilization, and achieve sustainable national economic development. Select excellent alloy powder for laser cladding repair, analyze the macro / microstructure characteristics, hardness and abrasion resistance of the laser cladding layer, and then grind the cladding layer to realize the remanufacturing of the lathe spindle

Repair Equipment Name: Imported 25m CNC Milling Machine

Repair material: alloy steel (60 #)

Basic situation of repair: Due to the equipment's long-term wear and tear on the inner wall of the working spindle, which is 0.5mm on one side, the traditional process cannot be repaired after wear.

Repair requirements

1. The allowable deviation of the radial circular runout of the taper hole of the spindle after grinding repair is: 0.01mm at the proximal end, 0.03mm at 300mm at the far end, and 0.01mm at the axial series of the spindle;

2. After grinding and repairing, the surface roughness of the taper hole of the main shaft should not be less than Ra0.8, and the contact area should be not less than 75% by using a standard test rod coloring, and it is advisable to make contact with the big end;

3. The tolerance of the keyway width of the spindle end face is 270 ﹢ 0.025mm, and the parallelism tolerance is 0.01mm.

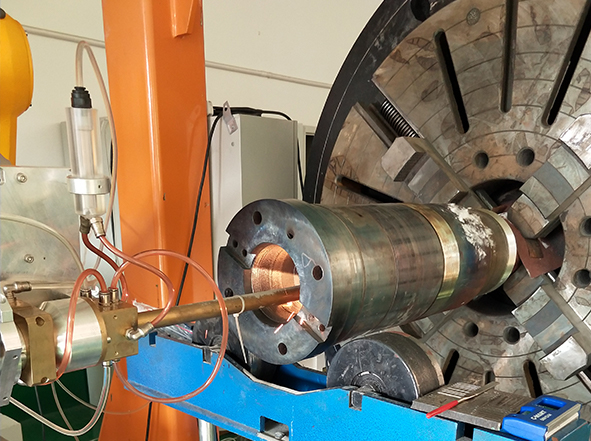

Inner hole repairing

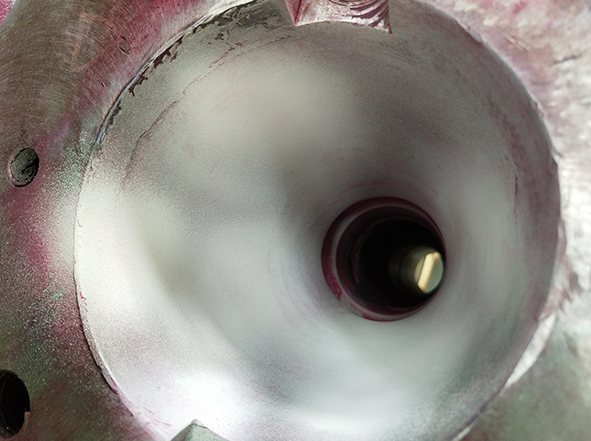

Flaw detection after cladding